| Sign In | Join Free | My udpf.com |

|

| Sign In | Join Free | My udpf.com |

|

| Categories | AC Servo System |

|---|---|

| Brand Name: | Vector |

| Model Number: | VEC-VC1-00623M-M-E / 80ME-00130A23-CF2 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 kit |

| Price: | To Be Discussed |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 500 kits/month |

| Delivery Time: | 3-5 work days |

| Packaging Details: | 280*208*78mm |

| Voltage: | 220V |

| Power: | 1 KW |

| Rated Current: | 5.4 A |

| Rated Speed: | 3000 rpm |

| Rated Torgue: | 3.3 Nm |

| Phase: | 3 Phase |

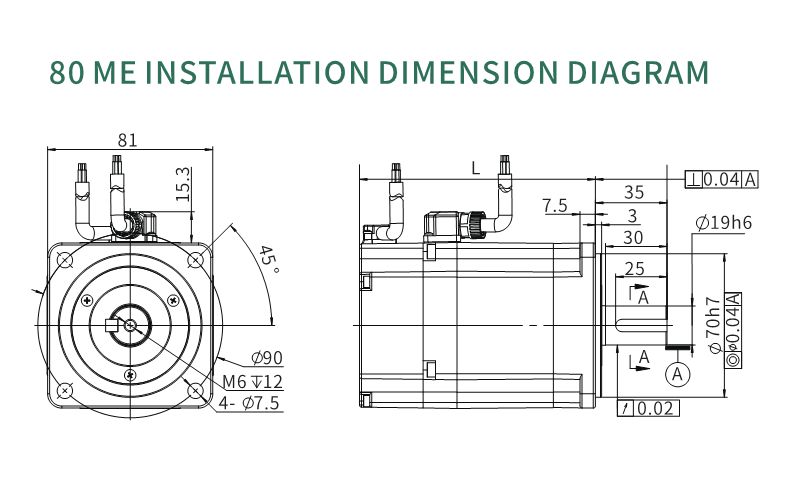

| Motor flange size: | 80mm |

| Communication Protocols: | Modbus/CANopen/EtherCAT |

| Encoder: | 17/23, 24 Bit Absolute Encoder |

| Application: | Printing machine |

1000W 3.3Nm Fully Closed Loop Servo System Servo Drive With Servo Motor

Servo Drive + Servo Motor

Power Covers 200W-110KW

Single/Three Phase 220V/380V

Modbus / CanOpen / EtherCAT

Products Description

| Products | AFully Closed Loop Servo System |

| Brand | Vector |

| Model No. | VEC-VC1-00623M-M-E / 80ME-00130A23-CF2 |

| Power | 1KW |

| Voltage | 220V |

| Phase | Three Phase |

| Rated Speed | 3000 rpm |

| Rated Current | 5.4A |

| Rated Torgue | 3.3 Nm |

| Communication Protocols | Modbus/CANopen/EtherCAT |

| Encoder | 2500 line incremental + Hall encoder; 2500 line incremental; 17/23

bit Tamagawa absolute encoder; 24 bit Nikon absolute encoder |

Servo Drive Description- Detaails about a Servo Drive, how to

select the Servo drive model and do installation?

● Install the driver on a dry and sturdy platform. Maintain good ventilation and

heat dissipation during installation and maintain good grounding.

● Please install in the specified direction to avoid malfunction.

● When installing, please ensure that the servo driver is kept at a specified

distance from the inner surface of the cabinet and other machines, otherwise it may cause fire or malfunction.

| Installation Environment Requirements | Atmospheric Pressure | 86~106kPa |

| Mbient Humidity | 0~55℃ | |

| Ambient Temperature | 0~90%RH | |

| IP Rating | IP20 | |

| Vibration | 0~4.9m/s^2 |

Accessories

| Accessory name | Image | ||

| Satandard Spare Parts | Power terminal |  | Adapt to E1,E2 structure drive |

| Cn3 encoder plug | Encoder plug on the driver side | ||

| Cn4 control terminal plug | Input/output signal terminals,user wiring | ||

| Encoder connection line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Power line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Drive monitoring line | Connect and adjust the software for remote monitoring and firmware update | ||

| Purchasing Spare Parts | USB to RS232 Adapter cable | If necessary, self purchase | |

| Ethernet communication line | If necessary, self purchase |

Certificates

1. CE (EU Safety Standard);

2. IEC/EN61800-5-1:2007 (Safety requirements for electrical,

thermal and energy in Section 5-1 of the variable

speed electric driver system), corresponding to the national standard GB12668.501-2013;

3, IEC / EN61800-3: 2004 + A1 (speed control electric driver system part 3 electromagnetic compatibility standards

and its specific test methods), corresponding to the national standard GB12668.3-2012.

Other Questions:

Q1. How to select the suitable model?

A: Please confirm your requirements for Rated Power, Current,

Voltage,

Torque and select the suitable model based our model list;

Q2. How to set the programming system?

A: Our Servo drive support the Global Communication protocols:

Modbus/CANopen/EtherCAT,

Please Just make the programming follow your experiences;

Q3. What's the power range about our servo system?

A: Our Power range covers 0.2-110KW, reach your requirements;

Q4. What's the encoder feedback interfaces we using?

A: We have multiple Encoder feedback interfaces, like :

incremental/wire-saving encoder,

17-bit/23-bit/24-bit absolute encoder, resolver encoder, etc.

|