| Sign In | Join Free | My udpf.com |

|

| Sign In | Join Free | My udpf.com |

|

| Categories | CCM Continuous Casting Machine |

|---|---|

| Place of Origin: | Jiangsu Wuxi China(mainland) |

| Brand Name: | Haijun |

| Model Number: | R8M 3 strands |

| MOQ: | 1 Set |

| Packaging Details: | Container |

| Delivery Time: | 2 months |

| Payment Terms: | T/T , L/C |

| Supply Ability: | 30 strands CCM per year |

| Certification: | ISO9001:2008 |

| Price: | Negotiable |

| Condition: | New |

| Voltage: | 380V |

| Weight: | 120t |

| After-sales Service: | Engineers available to service mach |

| Continuous casting machine: | with R 6m or more or less |

| Strand No: | from 1 to 8 |

| Feature: | high effencicy |

| Power(W): | 150kw |

| Item: | Electric continuous casting machine |

| CCM radius: | from R2m to R12m |

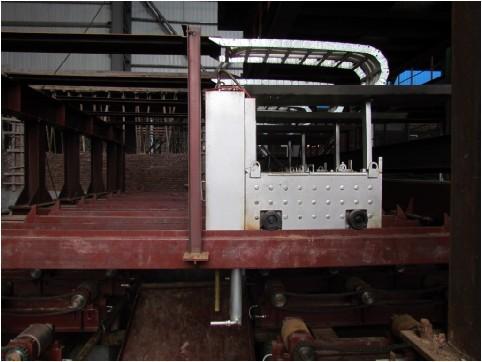

High Efficiency CCM Continuous Casting Machine R8M 3 Strands

Low energy and high efficiency

radius: R8M

Strand number: 3 strands

with ISO certification

safe operation

1. Basic standby technical parameters:

Steel billet casting machine radius | 8m |

Strand quantity | 3 strands |

Ladle support type | Ladle turret or Ladle car |

Tundish carriage | Semi-portal, cross sliding function |

Casting method | Metering nozzle, open casting |

Secondary cooling | Gas and water cooling , 2 adjusting circuit |

Withdrawal straightening machine | Totally 5 roller, progressive straightening |

Roll table | Chain group centralized drive |

Dummy bar | Rigid, with self-adapting dummy bar head |

Billet cutting | Hydraulic or flame cutting machine |

Billet conveying | Group centralized live roller table |

Cooling bank type | Simple cooling bed |

2. Technical process description and capacity of steel billet CCM

Induction furnace:

Nominal capacity | 40T |

Tap-to-tap cycle | 60min |

Furnace quantity | 3sets |

Production capacity

Working days | 330 days/year |

Average number of daily furnace | 24/day |

Production capacity | 400,000t/year |

3. Casting speed, productivity and strand quantity

R8m radius casting machine can cast steel groups of different specifications, the maximum casting speed is as follows:

Casting sectional area(mm) | 180x180 | 200×200 | 220×220 |

Casting speed(m/min) | 1.6 | 1.8 | 2.0 |

NO. | Billet size | Casting speed | hourly output (tons) | Daily output 20hour (tons) | Annual output(300days) (tons) |

1 | 180×180 | 1.6m/min | 21.98 | 439 | 131,700 |

2 | 200×200 | 1.8m/min | 27.13 | 543 | 162,900 |

3 | 220×220 | 2.0m/min | 36.47 | 729 | 218,700 |

The calculation results is the ideal state of the production, please according to own actual situation of adjustment.

Steel grade | Casting grade(m/min) | Effective deformation rate(ε) | Allowable deformation rate(εmax) |

Straight carbon steel | 1.8~2.5 | Please refer to the computational table | 0.25 |

Low alloy steel | 1.3~2.0 | Please refer to the computational table | 0.15~0.2 |

4. CCM equipment parts list

| № | Equipment name | Weight | Model and specification | Unit | |

| 1 | Ladle turret | 21T | set | 1 | |

| Hydraulic drive,with weighting | |||||

| 2 | Tundish arriage | 12.5×2=25T | set | 2 | |

| High and low leg type | |||||

| 3 | Tundish | 6×2=12T | set | 2 | |

| 4 | Slag Pot | 2.5T | set | 1 | |

| 5 | Long sleeve protection device | 0.3T | set | 1 | |

| 5 | Tundish baking | 5.3×2=10.6T | set | 2 | |

| 6 | Tundish nozzle | set | 2 | ||

| baking | |||||

| 7 | Casting operation | set | 2 | ||

| boxes cantilever | |||||

| rack | |||||

| 8 | 200×200 Mould | set | 3 | ||

| 9 | Mould cover | set | 3 | ||

| 10 | Oscillator device | set | 3 | ||

| 11 | Spray header | set | 3 | ||

| 12 | Oriented segment | set | 3 | ||

| 13 | Rigid dummy bar | set | 3 | ||

| 14 | Dummy bar storage device | set | 3 | ||

| 15 | Straightening and | set | 3 | ||

| withdrawal machine | |||||

| 16 | Straightening and | set | 1 | ||

| withdrawal machine | |||||

| common base | |||||

| 17 | Shears approach roller | set | 3 | ||

| 18 | Billet clamping | set | 3 | ||

| device | |||||

| 19 | Torch cutting | set | 3 | ||

| machine | |||||

| 20 | Collection cutting | set | 1 | ||

| head device and | |||||

| hanging pot | |||||

| 21 | After cutting roller | set | 3 | ||

| 22 | Transport rollerⅠ | set | 3 | ||

| 23 | Transport rollerⅡ | set | 3 | ||

| 24 | Knockout roller | set | 3 | ||

| 25 | Fixed bezel | set | 3 | ||

| 26 | Shifting steel | 6m length | set | 3 | |

| machine | |||||

| 27 | Collection cooling | set | 1 | ||

| bed | |||||

| 28 | Caster body cooling | include a backwash filter | set | 1 | |

| system | |||||

| 29 | Caster cover | set | 1 | ||

| 30 | Automatic Length | set | 3 | ||

| System | |||||

| 31 | Gas source processor | deal instrument gas | set | 1 | |

| 32 | Steel platform | 1 | |||

| Hydrauli,Lubrication,pneumatic system | |||||

| 1 | Host hydraulic station | set | 1 | ||

| 2 | The billet hydraulic station | set | 1 | ||

| 3 | Hydraulic lift tailgate | set | 2 | ||

| 4 | Centralized grease lubrication station | set | 6 | ||

| 5 | Hydraulic piping | set | 1 | ||

| 6 | Lubrication piping | set | 1 | ||

| CCM 3-Electric | |||||

| 1 | Operating station | ||||

| 2 | Software Package | ||||

| 3 | PLC | set | 3 | ||

| 4 | ET-200 PLC | set | 1 | ||

| Host hydraulic station ET-200 PLC | |||||

| 5 | Inverter | ||||

| ① | W-S machine inverter | set | 3 | ||

| (heavy type) power:11 kW | |||||

| ② | Shears approach roller inverter power:4KW | set | 3 | ||

|